FORCE MEASUREMENT BENEFITS

Keeping Welds Spot On

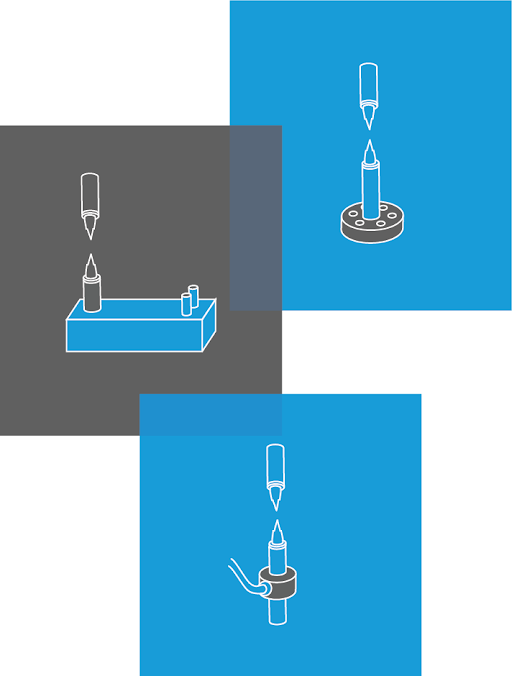

Transcell combines quality components and industry-leading engineering to solve challenges that compromise quality and performance of spotwelding.

Why Choose Transcell Spot Welding Solutions

- Exceptional Repeatability and Reproducibility

- Low Drift with Changes in Temperature

- Low Drift over Time

- Complimentary Signal Conditioning Products Simplify System Integration

- Custom Design and Private-Labelling Available

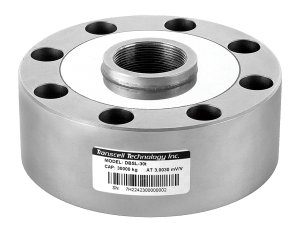

Pancake Compression Disk Load Cells

Pancake Compression Disk Load Cells